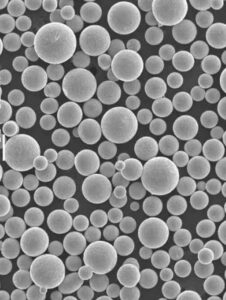

Narrow particle size distribution

Satellite-Free

Near-perfect sphericality

Oxidation resistance

Inconel 625

Inconel 625

BENEFITS

A family of austenitic powders that are similar in chemistry to EN 1.4404 and UNS

S316603. These materials are designed for processing in Laser Powder Bed Fusion

(LB-PBF), Electron Beam Powder Bed Fusion (EB-PBF) or Directed Energy Deposition

(DED) additive manufacturing systems. MetcoAdd 316L series products have been

rigorously engineered specifically to meet the demanding requirements for additive

manufacturing.

APPLICATIONS

■ Aerospace: Clamping elements and heat exchangers

■ Medical: Surgical tools and orthopedic implants

■ Transport: Maritime components

■ Tooling: Pressure injection dies and molds

■ Consumer: Jewelry and watch components

properties

| Parameter | Specification |

|---|---|

| Particle size range | 15-45 μm typical |

| Particle shape | Spherical morphology |

| Apparent density | > 4 g/cc |

| Tap density | > 6 g/cc |

| Hall flow rate | >99.9% |

| Oxygen content | <100 ppm |

data room

Applications & Case

Studies

They are a base material in applications that do not require any formability beyond minimal bending and/or roll-forming.

- Large and Small Electric Motors

- Generators

- Ballasts

- Transformers